M-ENGINE’s goal is to demonstrate the scalable fabrication of microcomb photonic modules using microtransfer printing. The overarching goal of the M-ENGINE project is to develop a compact microcomb photonic module (microcomb photonic engine), that is mass-manufactured with high yield and low cost enabling high-volume applications of comb lasers. The project objectives and the KPI related to each objective are described below.

| Key Performance Indicators | |||

| KPI # | Measurable Project KPI | Related Objective | M-ENGINE Target |

| KPI required by customers (based on initial discussions) | |||

| KPI 1 | Optical power per channel | 1 | -10 dBm |

| KPI 2 | Number of optical channels | 1 | 16 channels |

| KPI 3 | Power deviation across channels | 4 | 0 dBm |

| KPI 4 | Optical Signal-to-Noise Ratio | 4 | >35 dB |

| Technical Validation | |||

| KPI 5 | Optical Conversion Efficiency | 1 | 20% |

| KPI 6 | Coherent Modulation format supported | 4 | 16 QAM. |

| KPI 7 | The yield of MTP printed comb sources | 2, 3 | >80% |

| Business Validation | |||

| KPI 8 | Cost per M-ENGINE PIC with MTP at wafer level fab to meet customer needs | 2, 3, 5 | < 300 Euro |

| KPI 9 | Letters of Interest from future customers | 5 | 10 |

| KPI 10 | Customers that tested the initial prototype | 5 | 5 |

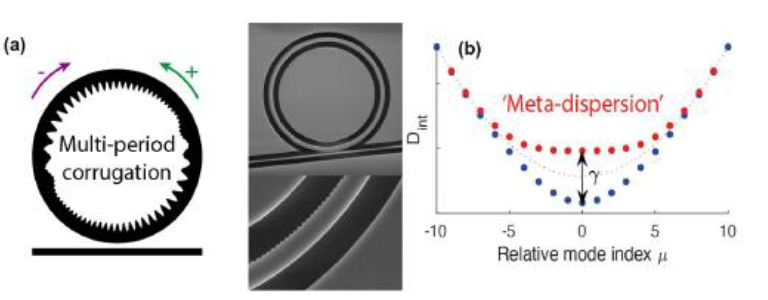

(a) Schematic drawing of a PhCR. The shape of the corrugation sets a spectral reflection profile. On the right, scanning electron microscope images of such structures.

(b) The spectral variation of the reflection modifies the effective dispersion (or meta-dispersion) via mode splitting.

Figure 1

Objective 1: Development of a high-performance microcomb chip compatible with MTP.

The consortium will develop an optimized photonic microcomb engine architecture, based on three main elements – (i) silicon nitride (SiN) passive photonic integrated circuit (PIC) that serves as the common substrate for the entire assembly. The PIC incorporates bus waveguides for optical routing, along with micro-resonator engineered for highly efficient, high reliability, and spectrally tailored comb generation. (ii) InP high-power pump lasers for microresonator driving, and (iii) InGaAs photodiodes (PDs) for microcomb monitoring purposes.

Objective 2: Establish a microtransfer printing process for the microcomb engines.

The project delivers a scalable and low-cost MTP process for the microcomb engine, including a choice of external sourcing partners for three assembly components (SiN passive PIC, a pump laser, and PD), development of the MTP stamps, order of component placement, final metallization process, and chip dicing.

Objective 3: Integration of microcomb photonic engine in a device-level solution.

Diced generic microcomb modules packaged in a butterfly-type housing will create a device-level solution for performance testing. A test bench with all required electronics will be developed to use the generic M-ENGINEs in the application demonstration together with consortium partners.

Objective 4: Performance testing of microcomb photonic engines for optical data transmission.

DCU will test final devices against key performance metrics required for high-capacity optical data transmission such as signal-to-noise ratio, optical power flatness, and bit error rate. External discrete components will be used to integrate generic microcomb devices in the corresponding infrastructure to test their performance in a relevant environment.

Objective 5: Business Validation

Once an early prototype is available and initial tests by DCU look positive then ELA and XC will focus on getting it in the hands of early adopter customers immediately. The consortium will not wait to have the perfect product as early feedback is more important.